About Our Factory

Minimising waste

Our factory has achieved ISO14001 environmental accreditation and is audited annually to ensure constant improvement. We minimise the waste we produce and recycle what we can wherever possible. We prefer the use of materials where all manufacturing waste has a secondary use or will be recycled, such as products made from aluminium, bamboo and wood. We have reduced our paper usage by approx 75% in the last 2 years and will continue to develop our internal technology to run our factory as paper free as possible.

Energy & resources

Our factory is heated by a biomass boiler using only pellets made as a bi-product of UK pallet making. Low energy lighting is used throughout, we are well insulated and when machinery needs replacing, energy efficiency will play a major part in choosing alternatives. Very little water is required in our production but use is always monitored for savings to be made.

Our people

We provide a safe and friendly place to work with good working conditions. All those who work in our factory have a contract of employment with us for fixed hours and a comprehensive staff handbook outlining all aspects of working for the company. We aim to provide opportunities within the company for those who wish to progress and full training is always provided. Those responsible for factory health and safety are fully trained to ensure safe working practices throughout. We only create secure employment for the long term and do not use agencies – no homeworkers are used in the production of any products on this website.

Our suppliers

We also treat our suppliers fairly and with respect, looking to forge long term partnerships with like minded companies who reject any form of bribery and can demonstrate there is no slavery within their supply chain.

The finished products

We ensure our products are safe and fit for purpose. We comply with REACH and all other regulations relating to the safety of what we make. Our company is ISO9001 quality certified and we will ensure that the systems and processes are in place so that the product you receive is what you expect.

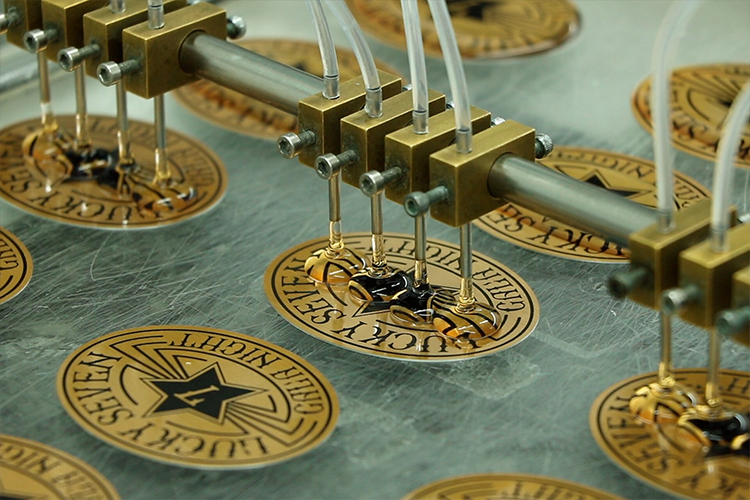

Inside Our Factory